The new Double pony

More robust, more affordable, and Made In France

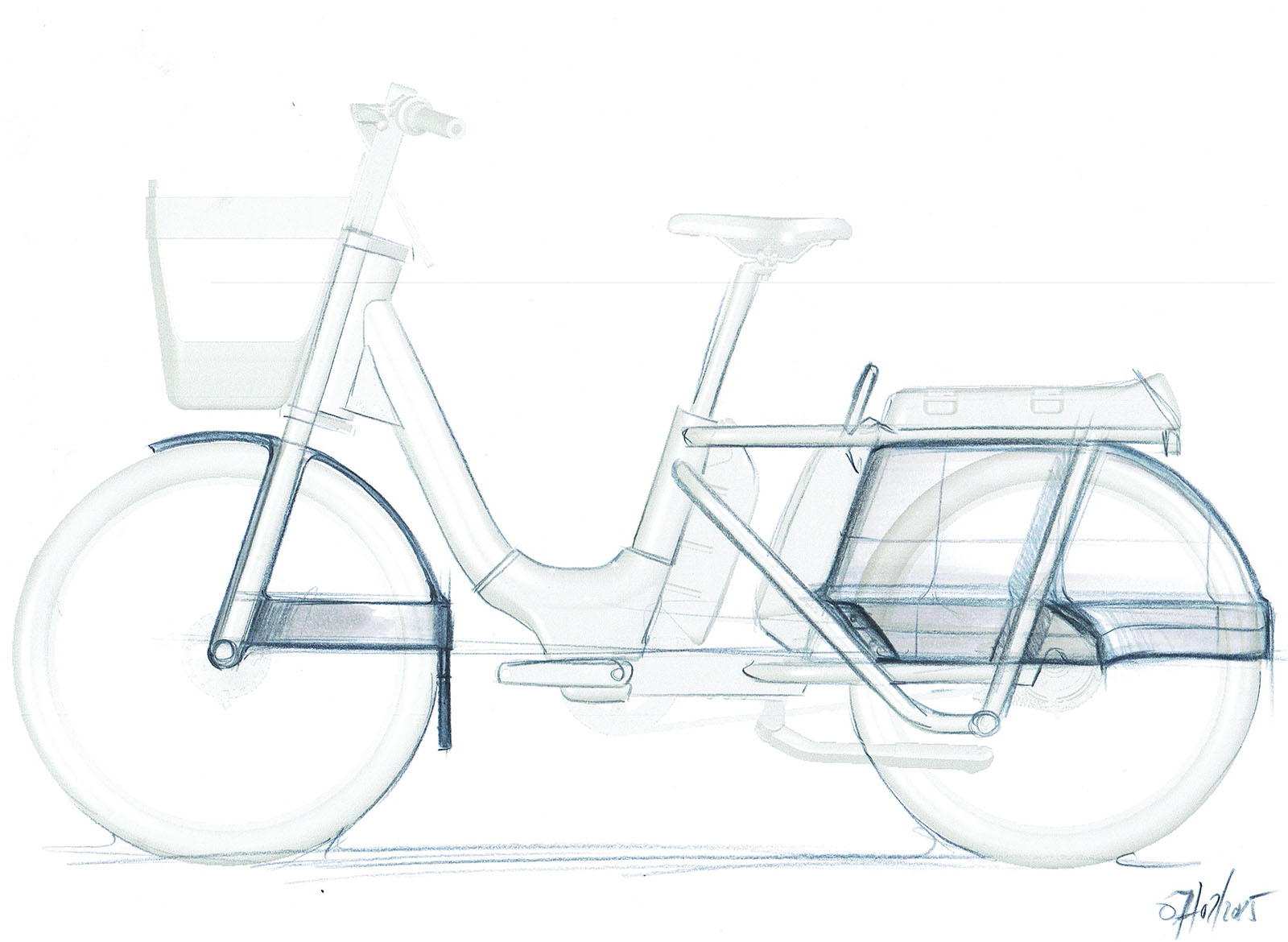

In September 2024, pony and Antidote Solutions started working together with an ambitious project in mind: twelve months to release an upgrade of Double pony, the only two-seater ebike designed for sharing that made the brand a success.

October 2025, on the occasion of the official launch of the new Double pony, Paul-Adrien Cormerais and Alex Guiral looked back at the key factors that made it possible to release this new model in record time.

Key factor n°1: Teamwork and challenging each other

In 2024, three years after the launch of the first Double pony, the French company wants to develop a new version of its flagship product. The ambitious goal is to offer users the best self-service bicycle on the market, bring production back to France and Europe, and make this project a success within a year!

Connectivity, robustness, ease of repair: designing a new self-service bicycle presents engineering and industrialisation challenges that are very different from those of a consumer bicycle. These challenges are all the greater as the aim is to develop a truly unique bicycle: the only electric-assist bicycle equipped with a passenger seat.

To succeed, Paul-Adrien, co-founder of pony, wishes to surround himself with the best partners. He then contacted Antidote Solutions : “for us, it was obvious that we should call on the reference bicycle design office. Alex Guiral helped us define the specifications. He also supported us during the ideation phase, mechanical design, sourcing, test protocol definition, and industrialisation. The Antidote Solutions’ project team worked closely with our own internal teams. They were attentive and listened carefully to adapt to our working methods and constraints. Together, we challenged ourselves to create the best self-service bicycle on the market.”

Key factor n°2: optimising the reliability of the new Double pony

As the only French company providing self-service bicycles, pony has always focused on quality of service and operational excellence. One of the key factors in satisfying users and enabling them to see self-service cycling as a genuine alternative to cars is the availability of bicycles on the streets.

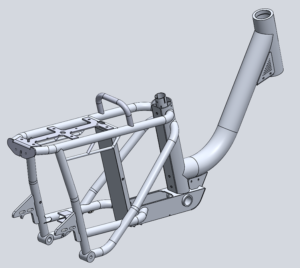

The new version of the Double pony must therefore enhance the robustness of the bicycles and take future repairs into account right from the design stage, in order to reduce the time bicycles spend out of service in maintenance centres.

“We conducted in-depth analysis of each component, said Alex Guiral. Self-service bikes are often mishandled and misused. A front basket can quickly become a dustbin, and a seat fork can be used as a passenger seat. We have to consider as many scenarios as possible in terms of risks, dangers, and weak points. These are constraints that we don’t encounter when working on ranges sold in retail stores.”

Key factor n°3: identify the right suppliers

“The cycling industry is very confidential, said Paul-Adrien. Antidote Solutions has the ability to find the right information, the kind that stays under the radar.” Alex Guiral continues the story: “ We mobilized our network to accelerate the project, both in terms of sourcing and technical expertise. Our added value as a bicycle design office lies in our comprehensive knowledge of the industry in Europe and Asia. Pony had several references, contacts with several suppliers, and the opportunity to exchange ideas with other players in the cycling industry to obtain qualified feedback on after-sales service in particular. We visited factories with them before they chose their suppliers, mainly in France and Europe, in accordance with the specifications initially defined by Pony.“

Key factor n°4: lowering production costs by relocating

While the initial specifications include the relocation of production and the use of as many European or French components as possible, they also set the objective of reducing the bicycle’s production cost. And this challenge has been met: bringing production back has resulted in a bicycle that is €200 cheaper than if it were manufactured in Asia.

The results:

- the new Double Pony are painted and assembled by the Manufacture Française du Cycle (in the Loire-Atlantique department in western France).

- lock controllers are manufactured in Strasbourg,

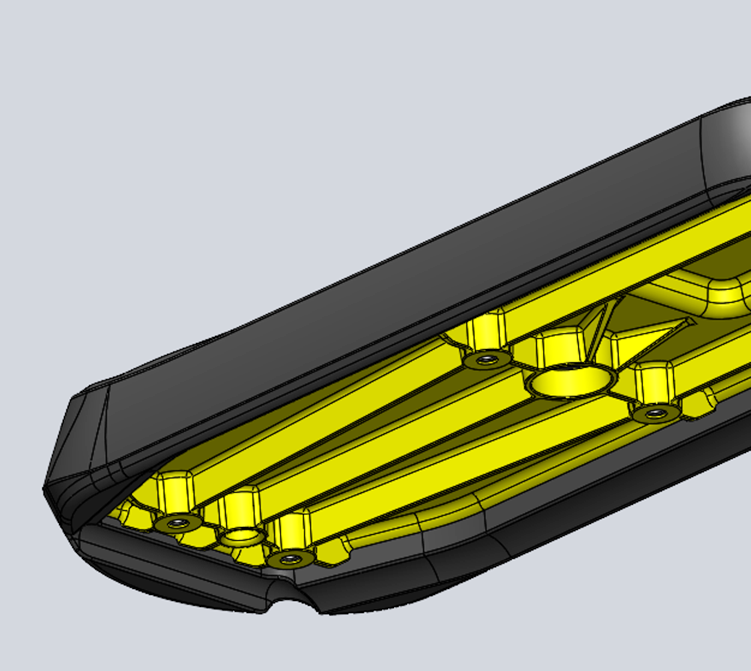

- batteries comes from Angoulême,

- seats are produced in the Pays Basque region,

- wheels are manufactured in Saint-Etienne.

The last word is for Paul-Adrien Cormerais :

“this is a significant project, we gave ourselves the means to succeed, and the result is clear: a simpler solution to produce with a new design and a more elegant aesthetic. I am eager to move on our next projects and to keep working together to enhance improvements in urban mobility”.

The Double Pony project

the segments in which we are involved

Brand Strategy

Product Strategy

market studies for brand and product

brand positionning

“go to market” strategy

brand indentity and communication

Engineering

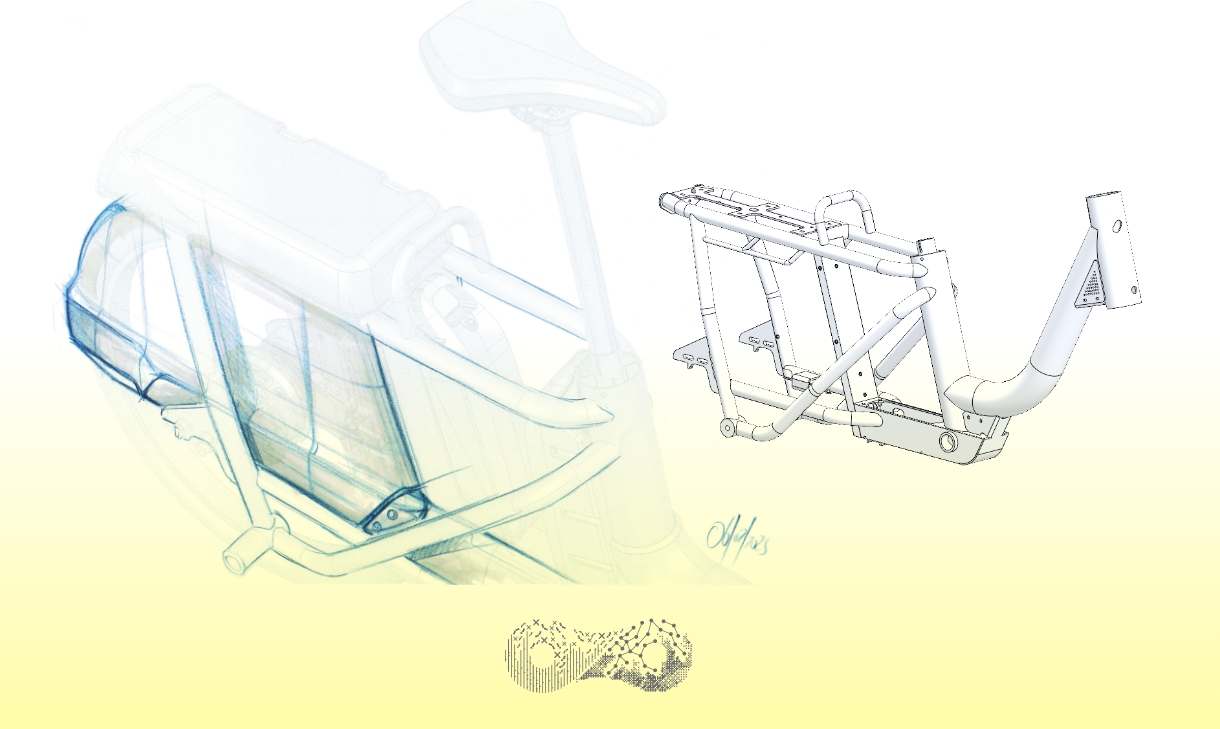

technical design

3D modeling

FEM analysis

product management and component sourcing

nomenclature et documentation technique

Prototyping and fine-tuning

prototyping supervision

shakedown and initial proof testing

“on field” testing

fine-tune set up

Industrialisation

manufacturing process

production engineering

supply chain set up d’approvisionnement

product certification support

manufacturing supervision